MIHPT Does More Than Refine Your Conceptual Site Model

By: Eliot CooperMost users of MIHPT systems understand how to interpret the data to optimize the conceptual site model (CSM), but they may not be taking full advantage of it. The next step—that is often missed—is applying these outputs to the overall optimization of the in situ remediation design.

In this blog post, we’ll cover how you can get the most out of your MIHPT data. If you find this intriguing, watch the webinar where we dive deeper into the specifics of how to use your MIHPT data to select the most appropriate amendments and delivery methods.

The MIHPT system provides two critical pieces of information that help remediation professionals select in situ amendments and related delivery systems: 1) contaminant detector responses and 2) critical data relative to the hydraulic conductivity required to fully optimize an in situ remediation design.

Often amendments are selected based on chemical efficacy for the target contaminants - bench scale testing. Often, the amendments can't be effectively distributed in the target interval, or the delivery technologies used are not able to achieve distribution expectations.

Selecting delivery pumps and tooling prior to the selection of amendment chemistry improves in situ remediation performance. The following tables align the physical form of amendments with effective distribution approaches (pumps and tooling) at above or below fracture pressures considering target interval hydraulic conductivity.

PHYSICAL FORM OF AMENDMENTS

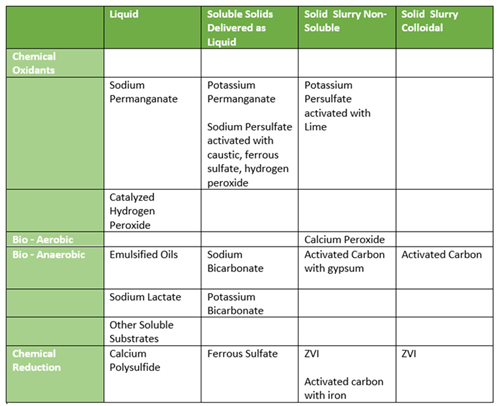

Today’s amendments come in liquid, solid, and a solid slurry form.

- Many of the solids are soluble in water at certain concentrations and are distributed as a liquid.

- Other solids are not soluble, but diluted with water and distributed as a solid slurry.

- Some solids amendments, such as ZVI, are mixed with other liquid amendments like emulsified oils, and then distributed as a solid slurry.

- In some cases, their small particle size (e.g. colloidal) allows them to be injected as a liquid that can be delivered and move through the soil pore space by advection.

In Situ Amendments Physical Form

PUMPING SYSTEMS

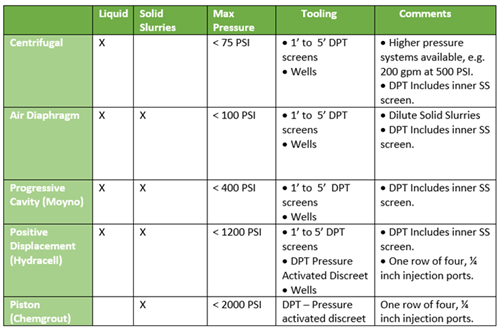

There are different types of pumping technologies used for the delivery of liquid and solid slurries. They provide a wide range of flow rates and pressures and can pump a variety of particle sizes of non-soluble solid amendments. In addition to pump selection, the injection tooling or injection well capabilities are part of the integration into an overall delivery system.

In Situ Amendment Pumping System and Associated Delivery Approaches

FRACTURING OR NO FRACTURING

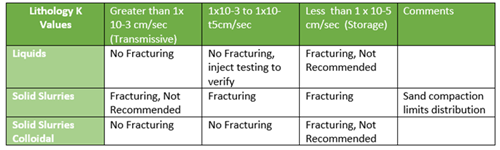

A key design consideration in pump and amendment selection is the target interval hydraulic conductivity. As a general rule, the transmissive (high K) zones are best targeted with liquids or colloidal solid slurries, and the storage (low K) zones are best targeted with solid slurries.

Recommendations for Liquid and Solid Applicability and Pump Pressures Considering Target Interval Hydraulic Conductivity

HETEROGENEITY COMPLEXITY

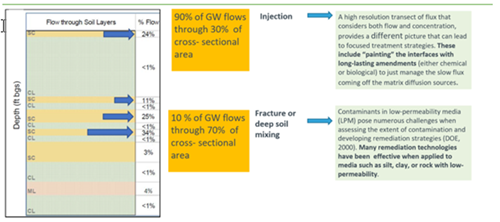

The presence of matrix diffusion or dark matter significantly impacts overall remedy performance. It is important to understand how contaminant mass is distributed in transmissive (high K) versus storage (low K) zones and how their distribution impacts setting remediation expectations. Then, a critical design consideration is made about where to target the contaminant mass. You may consider the transmissive zone to reduced mass flux, or the storage zone to reduce back diffusion, or both. If both are targeted, you will have to evaluate if a one size fits all amendment and delivery approach will effectively achieve the necessary distribution, contact, and residence time.

"Dark Matter" In Situ Remedial Considerations After Advanced Characterization

Image from webinar, Dark Matter: How to Use Advanced Site Characterization to Identify & Design for Contaminants in Low Permeability Zones.

Remediation optimization is improved by taking advantage of high resolution site characterization (HRSC) tools like the MIHPT. If you’d like to learn more, join me next week for our next webinar, How to Select Liquid & Solid Amendments and Pumping & Delivery Methods Based on MIHPT Data.