The client’s mission is to locate new mining opportunities in North America that result in the discovery of more natural resources, whether they be for coal, copper, diamonds, or nickel. Discovery and mining of these minerals helps industries like cellular products, transportation and healthcare stay alive to support everyday life. In this project, the team was able to show the client how combining sonic with traditional drilling techniques can accomplish more in less time, and provide high quality samples for further exploration needs - all while battling extreme winter conditions and limited access issues.

PROJECT GOALS

- Obtain core samples from depths of 6500 feet for mineral exploration

- Install three monitoring wells for groundwater and overburden information

PROJECT CHALLENGES

- Extreme winter conditions with temperatures that drop below zero degrees Fahrenheit

SOLUTIONS AND RESULTS

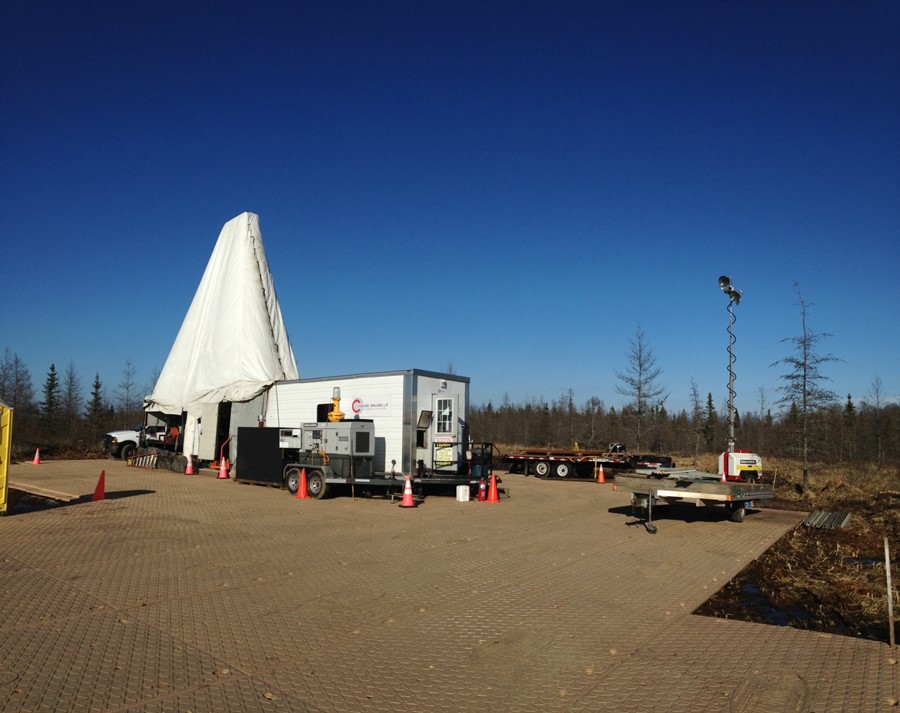

To address the weather challenges, the team took a few different approaches. In order to allow the drills to run 24 hours a day due to desired depths, custom drill and tooling enclosures were made to insulate equipment and crews from the extreme conditions. Large portable diesel-powered heaters maintained warmer temperatures in the working areas. Strict health and safety guidelines were followed to prevent injury and illness: additional personal protective gear, mandatory check-in schedules, frequent preventative maintenance on all vehicles and rigs, and a full stock of spare parts.

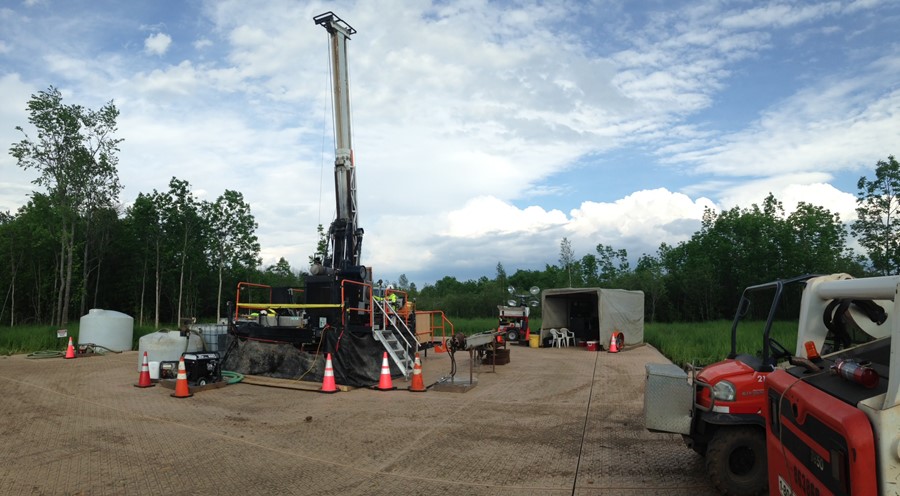

Sonic drilling was selected for sampling and casing off the overburden and groundwater before coring began. Sonic is ideal for fast drilling through overburden, or the material that lies above an exploration area, while setting casing so the core rig can drill rock immediately. High speed diamond coring was selected for the core work as it is ideal for the common semi-consolidated/cemented rock to hard rock environments of mining. Unique to mining coring projects, diamond coring allows for a variety of drill bits and platform configurations that can overcome the toughest conditions.

This two-stage approach minimized drilling time and maximized depth to provide the client with the most information. Mini sonic rigs, which have a smaller footprint, were used to reach less accessible sites and lessen environmental impact.

Crews achieved twice the original estimated drilling footage each season through the use of sonic and diamond coring technologies. Sonic drilling delivered high-quality overburden core samples proving extremely detailed information of subsurface conditions. These core samples and additional water samples provided hydrologic information in clients’ other mineral exploration projects.