Innovative Technologies for the Assessment of Petroleum Releases

By: Rob Herbert, PGIn an article for the Colorado Environmental Management Society, board member and Colorado Division of Oil and Public Safety (OPS) Remediation Supervisor Rob Herbert discussed the technological advances in site characterization that are driving the organization's return on remediation investment. High-resolution site characterization (HRSC) and LNAPL transmissivity testing have played a critical role to achieve site closure in less time with lower overall costs.

This article was first published by the Colorado Environmental Management Society in their September 2019 newsletter and is reprinted here by permission of the author.

The OPS implements a risk-based corrective action program to protect human health and the environment from petroleum releases from OPS-regulated storage tanks. Over the last decade, OPS has focused on release prevention with more frequent compliance inspections for high-risk facilities, implementing incentive programs for upgrading spill prevention equipment and permanently removing tank systems, and reimbursing tank owners/operators for costs to remove aging underground storage tank (UST) systems. These efforts have contributed to a decrease in open release events from 1,200 in 2008 to less than 600 in 2019. In addition, the Petroleum Brownfields Program supports the assessment, cleanup, and redevelopment of former gas station sites with abandoned unregulated tanks, and the installation of EV charging stations. Relatively recent technological advances in site characterization are being utilized by OPS to achieve closure of release events in the most timely, cost-effective, and technically efficient manner. Two of these technologies are discussed in this article: LNAPL (light non-aqueous phase liquid) transmissivity testing, and high-resolution site characterization.

LNAPL TRANSMISSIVITY TESTING

A common obstacle to closing petroleum release events with measurable LNAPL is meeting the nebulous EPA standard of recovering LNAPL to the “maximum extent practicable” or MEP (40 CFR 280.64). The EPA has left the interpretation of the MEP standard to state and tribal implementing agencies. Historically, LNAPL recoverability has been associated with in-well LNAPL thickness measured in monitoring wells. However, as presented by the Interstate Technology and Regulatory Council (ITRC, 2009 and 2018), measured in-well LNAPL thickness does not correlate with actual LNAPL thickness in the subsurface and is a poor indicator of LNAPL recoverability. As a result, many implementing agencies have a backlog of petroleum release sites that are not effectively approaching site closure because of the presence of measurable LNAPL in monitoring wells.

To help to implement agencies define “maximum extent practicable,” ITRC identified LNAPL transmissivity (Tn) as a metric to evaluate LNAPL recoverability. Tn depends on soil type, LNAPL type, LNAPL saturation, and thickness of mobile LNAPL and can be measured and analyzed using the American Society for Testing and Materials (ASTM) E2856-13: Standard Guide for Estimation of LNAPL Transmissivity and an associated workbook developed by the American Petroleum Institute (API). Based on empirical data, ITRC proposed a Tn performance metric of 0.1 to 0.8 ft2/day (~1.5 gals/day), below which LNAPL recovery is considered technically impractical.

OPS has adopted the ITRC Tn metric and considers LNAPL recovery impractical for Tn values below the proposed ITRC range. In these cases, the saturation-based LNAPL concern has been eliminated, and the focus of the release event shifts to addressing the compositional concern to receptors posed by the primary contaminants of concern, which are benzene, toluene, ethylbenzene, xylenes (BTEX) and methyl tertiary butyl ether (MTBE). Based on ITRC’s LNAPL Technical/Regulatory Guidance, OPS has developed an LNAPL policy that allows for the closure of release events with measurable LNAPL left in place if recovery has been determined to be impractical based on calculated Tn values, and the composition-based petroleum risk to receptors has been addressed.

HIGH RESOLUTION SITE CHARACTERIZATION

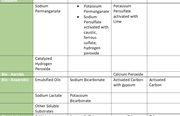

OPS has found high resolution site characterization (HRSC) tools to be more effective than conventional site assessment methods for characterizing petroleum releases in Colorado. The primary HRSC tools include:

- MIP (membrane interface probe) for dissolved phase plumes,

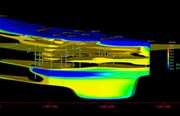

- HPT (hydraulic profiling tool) for estimating hydraulic conductivity, and

- LIF (laser induced fluorescence), UVOST (ultraviolet optical screening tool), and OIP-UV (optical imaging profiler ultraviolet) for defining LNAPL.

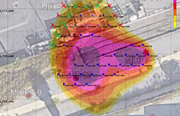

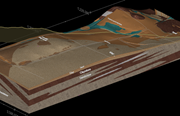

While utilizing HRSC tools may result in higher up-front assessment costs, these tools enable a more accurate definition of release source areas and subsurface contaminant distribution, which leads to better conceptual site models, identification of targeted treatment areas, and implementation of more technically efficient, expedient, and cost-effective corrective action plans. In addition to defining source areas and targeted treatment areas, HRSC tools can be used to characterize hydraulic conductivity at release sites. For example, the MIHPT tool is a combination of the MIP (membrane interface probe) and the HPT (hydraulic profile tool) to better characterize heterogeneity of hydraulic conductivity. Understanding the hydrogeology of the release site provides the foundation for decision-making to select appropriate remedial options and determine remedial endpoints by identifying low-permeability contaminant storage zones and higher permeability transport zones.

OPS promotes HRSC not only at new release sites but also at older sites where conventional site characterization methods have resulted in ineffective remediation efforts due to inadequate source area definition and poor hydrogeological characterization. At some of these older legacy sites, HRSC has been used to re-evaluate and define source areas and LNAPL pockets that were missed using conventional assessment methods, and to identify targeted treatment areas to implement more effective remedies to achieve site closure.

Although some HRSC tools have been available for several years, advances in computing and supporting technologies have significantly improved data analysis and presentation. In addition, HRSC tools can collect much more data than conventional methods within the same time frame, and costs have decreased while the number of contractors offering these services has increased. Based on OPS experience, the cost of HRSC ranges from $4,000 to $6,000 per day depending on the contractor bid package. However, the effectiveness of any corrective action plan is contingent on thorough site characterization. Embarking on petroleum cleanups can cost several hundred thousand dollars; doing so without spending a fraction of that upfront on a thorough site characterization is being penny-wise and pound-foolish.