In Situ Stabilization: The Future of Sustainable Remediation and Carbon Reduction

By: Cascade EnvironmentalAs an environmentalist, a project manager for Cascade Environmental, and a member of Cascade’s Sustainability Council, I believe that those of us who work in environmental remediation, as well as stakeholders in known contaminated sites, can make a significant difference in reducing the effects of climate change. One of the ways we can do this is by considering the impacts of our remedies for our sites’ contaminants of concern (COCs).

What is Sustainable Remediation?

Sustainable remediation balances community goals, economic impacts, and environmental effects of remediation activities from project planning through design and implementation. Cascade works closely with environmental consultants, engineers, and clients to identify and incorporate a wide range of sustainability best practices which our crews can implement in the field.

One of our inspirations is the Environmental Protection Agency’s “Principles for Greener Cleanups” which “provide[s] a foundation for planning and implementing cleanups that protect human health and the environment while minimizing the environmental footprint of cleanup activities.”

Of course, cleaning up sites is beneficial for the environment; however, remediation activities require materials, fuel, and water. The use of these resources creates its own negative impact. The EPA says, “All cleanup approaches, and all elements of the cleanup process, can be optimized to enhance their overall environmental outcome.”

In Situ Stabilization: Sustainable Choice

Our clients have the opportunity to choose from a wide range of remediation technologies to support their sustainable remediation goals. One option is In Situ Stabilization (ISS), which eliminates a majority of off-site disposal of source waste material to extend the life of landfills and/or incinerators and which lowers the high fuel usage and safety risks associated with waste transportation.

Let’s say you’re a site owner with COCs on your property (or an environmental consultant hired to address the issue). One way to handle it is by excavating the contaminated soil and hauling it in trucks to another state where it can be legally buried. To me, that is just making the environmental contamination someone else's problem – kicking the can, or in this case, the hazardous waste, down the road, literally.

Instead, you have the option to treat the contaminant in place and still achieve your goals for the site, including redevelopment.

How does ISS work? ISS creates a contained ‘monolith,’ essentially, we turn the contaminated soil into a giant brick which stays right where it is with no need to remove it and haul it away. The amendments we use break down contaminants into their least soluble, least mobile, and least toxic form. ISS also turns the soil into a great subsurface for commercial or industrial construction. You can put a warehouse on top of that and it’s safe for both the environment and for human interaction.

Carbon Comparison: ISS vs Dig-and-Haul

When a potential client asked us to include 2,000 trucks in a project proposal, I was curious about whether I could demonstrate the sustainability benefits of ISS compared to dig-and-haul. To me, the sheer amount of trucking involved in removing contaminated soil and transporting it elsewhere defeats the purpose of reducing environmental harm.

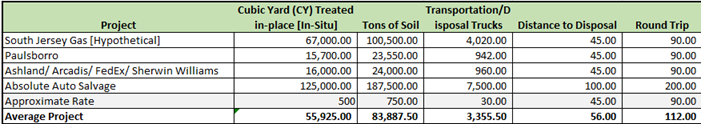

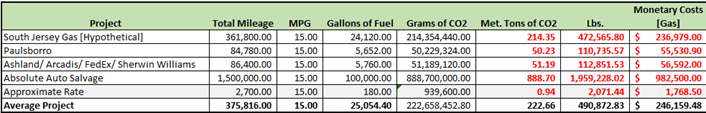

On a current project, where we’re using ISS, I calculated that we only needed 100 trucks versus nearly 1,000 which would have been necessary for excavating and hauling, requiring a lot of fuel and a lot of mileage. So, I looked up how many gallons of fuel it would take to haul the 24,000 tons of contaminated soil a distance of 90 miles round-trip (see Figure 1 below). The total was almost 6,000 gallons. Then I calculated how many grams of carbon dioxide (CO2) would result from burning those 6,000 gallons. The total was just over 50 metric tons of (CO2).

Figure 1

It's hard to picture what 50 metric tons looks like. Imagine a cube almost as tall, wide, and deep as a telephone pole. That’s how much space it would take to hold a metric ton of CO2. (Note that a metric ton is 2,205 pounds, a bit more than an American ton at 2,000 pounds. Also, note that CO2 emissions are heavier than the original fuel burned. This is because during the combustion process, each carbon atom in the fuel combines with two oxygen atoms in the air to create CO2.).

Today, everybody wants to know how many metric tons of carbon you produce as a company or industry. For this one project, by conducting ISS rather than excavating and transporting the contaminated soil for disposal, we avoided releasing 50 tons of CO2 into the atmosphere. That’s impressive. Now, imagine making that sustainable choice for multiple projects across the country.

Cascade’s Focus on Sustainability

Cascade’s Corporate Sustainability Program, Compass™, connects clients with innovative options for resource conservation, environmental remediation, and responsible waste management.

I am proud to work for an environmental company like Cascade, where we don't just execute environmental and remedial work well; we evaluate and present the sustainability of our efforts on a professional level. We recently published our comprehensive annual Corporate Sustainability Report. The report outlines Cascade’s first Climate Action Plan (CAP), which includes carbon inventory, greenhouse gas (GHG) emissions reporting, and a three-year roadmap for carbon reduction. The CAP is a tool to identify the risks and opportunities associated with climate change and then position our organization for climate resiliency.

As an environmental nerd, I love Cascade’s Corporate Sustainability Report, but everyone can benefit from reading it to understand how we prioritize this issue as an integral part of doing business every day.

Sustainability is not just a buzzword; this term can define how companies demonstrate their productivity as well as their resilience and efficiency in an uncertain future.

Making a Difference

Greenhouse gas emissions are a major driver of climate change – and as we’ve all seen in the news, the effects of climate change are changing the way people live all over the planet. With ISS, you can avoid releasing tons of CO2 into the atmosphere. If you're concerned about sustainable remediation, you should consider ISS in your evaluation of potential remedies. ISS lets us fix a problem where it is, instead of moving it somewhere else and, in the process, causing yet more environmental damage and harm to human beings.

I care about the environment at work and on my own time. My focus in my career will always be centered around sustainable and environmentally sensitive best business practices because I believe it’s the right thing to do for our long-term survival. The planet will survive the destruction we’ve brought to it, but human beings might not be here to enjoy it. That’s what keeps me up at night and it’s what makes me passionate about sustainability.

At Cascade, we have made significant progress towards our sustainability goals. Looking ahead, we are excited to continue pushing ourselves to the next level and beyond. I believe that the choices we make will have a positive impact on the world around us.