3 Things You Need to Ask Every Contractor Before Hiring Them for Your Environmental Fracturing

By: Eric Moskal Is environmental fracturing in your remediation project scope? Pneumatic fracturing can absolutely improve your remediation results when applied correctly. When seeking help with permeability enhancement, it's crucial to vet contractors so you don't incur unexpected costs, experience delays or fail to safely implement the technology. The three questions provided below can help you evaluate contractors and find one you trust for this specialty technology.

Is environmental fracturing in your remediation project scope? Pneumatic fracturing can absolutely improve your remediation results when applied correctly. When seeking help with permeability enhancement, it's crucial to vet contractors so you don't incur unexpected costs, experience delays or fail to safely implement the technology. The three questions provided below can help you evaluate contractors and find one you trust for this specialty technology.

What Experience Do You Have in Overcoming Low Permeability Formations?

Contractors who thoroughly understand the processes of permeability enhancement, its application in different geology and the selected remedial amendment can more efficiently and accurately address the difficulties presented by low permeability.

An experienced contractor should provide project examples of applying permeability enhancement to support the emplacement of the selected remedial amendment at similar sites, depths and geologies. Before moving forward, an experienced contractor can tell you if your situation is a good fit for this process and offer alternatives if not.

How Do You Implement Environmental Fracturing in the Field?

Permeability enhancement can be implemented with a remediation technology known as pneumatic fracturing. Fracturing increases the bulk permeability of the subsurface by creating a network of pathways in the subsurface for the amendments to follow.

The contractor’s experience, selected amendment and site-specific data evaluation are used to determine the necessity and applicability of permeability enhancement.

An experienced contractor will have equipment rated for the designed pressures, chemically compatible with the selected amendments, and appropriately sized for the scale of the field event.

What Background Information Do You Need From Me?

While it may require some additional digging for data, a contractor interested in learning about the site’s background shows that they’re experienced and proactive about properly tackling the problem. Sharing details about the site contamination history, amendments used in the past, and previous attempts’ successes or failures are critical in designing a more informed approach.

Suppose wells on the property weren’t constructed correctly or intended for a specific purpose. In that case, they may not be conducive to performing permeability enhancement within the radius of influence. The process could ruin the wells and daylight injection amendment, a costly issue. A contractor who wants this kind of information ahead of time has experienced many different conditions and wants to head off potential problems.

Pneumatic fracturing must be performed carefully by experienced remediation experts, and it can be an ideal solution when executed properly in the proper circumstances. The importance of having candid two-way conversations using these three questions and any other questions that arise during a remediation project cannot be overstated. Open communication is key to a successful project. Putting these three questions to use will help vet your potential contractors to complete your job on time and within budget.

If you’d like to learn more about our experience with pneumatic fracturing, read this permeability enhancement project highlight. And if you’re ready to begin evaluating contractors, let us know by requesting a quote.

About the Author

Eric Moskal

Director of Technical Experts

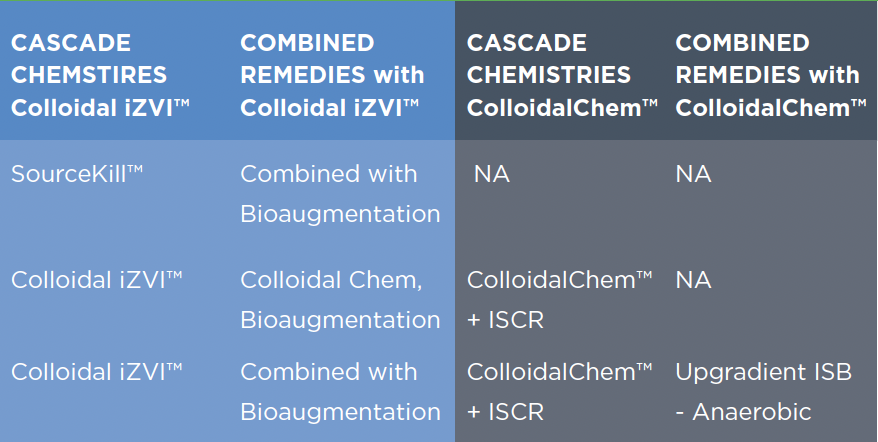

Eric Moskal is a Director of Technical Experts at Cascade. He specializes in remediation projects that involve large scale, difficult locations and conditions, and low permeability geology. In this role, Eric collaborates with his clients to identify a cost-effective, site-specific methodology for delivering amendments that will achieve their remedial goals. Previous projects have included everything from the site of a former corner gas station to personal residences to large federal sites.

Eric is a national expert on pneumatic and hydraulic emplacement of chemical oxidants, zero-valent iron (ZVI) and combined ZVI-bioremediation remedies for complex chlorinated solvent sites, as well as remediation engineered activated carbon for complex petroleum sites. He also provides pneumatic permeability enhancement of finer grained soils to optimize soil vapor extraction (SVE) systems for both hydrocarbons and chlorinated solvents removal.

Eric has over a decade of practical experience in the environmental services industry. He has extensive hands-on field experience overcoming site-specific challenges that become evident once field applications commence. Eric is an excellent resource for clients needing delivery of in situ solutions at sites where traditional injection is not viable