- Eliot Cooper

When it comes to in situ remediation, the injection equipment is just as important to a successful outcome as the amendments you’ve selected. Injection volume, pressure, and a homogeneous mixture are critical in optimizing amendment distribution and contact to achieve your remediation goals.

Advancements in injection system technology have proven successful for a wide variety of liquid and solid amendments and subsurface conditions.

In this pre-recorded webinar, remediation expert Eliot Cooper will discuss the innovations in injection technology and how these changes are benefiting consultants today. He will cover various aspects of injection systems, such as injection tooling, amendment mixing, manifolds, and downhole straddle packer systems.

For liquid or colloidal solid amendments in coarse-grained soils or fractured rock:

- High volume and moderate pressure redundant electric centrifugal pumps

- High volume and moderate pressure redundant electric progressive cavity pumps

- Hybrid systems where unexpected tight soils are encountered

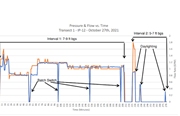

- Electric automated systems where precise pressure and control are needed for distribution and contact, like PRBs

For solid amendments in fine-grained soils or fractured rock:

- Electric and hydraulic piston pumps

- Pneumatic permeability enhancement with high-pressure nitrogen for overburden and bedrock fractures

- Hybrid Systems where unexpected transmissive zones are encountered