PRO Card

Cascade managers and clients are encouraged to use the online PRO Card to observe work processes, and identify if best safety practices and correct behaviors are in use. These cards are reviewed by the EHS team to ensure employees receive feedback and coaching when necessary on safety performance or compliance expectations.

JSI

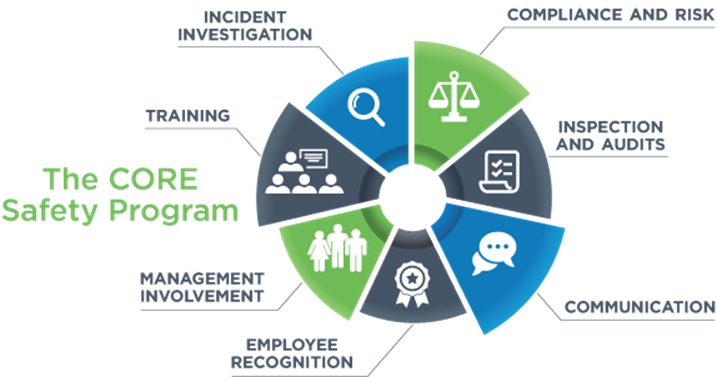

Job site inspections (JSIs) are conducted to ensure compliance with relevant regulations, policies and company procedures. Data gained from this process is used to improve the CORE™ safety program, including but not limited to risk assessment, hazard mitigation, training, site operations, SOPs & JSAs, and identification of best practices and job site compliance.

JSA

Job Safety Analyses (JSAs) are a key element of Cascade’s Hazard Recognition, Prevention & Control Program. These risk assessment tools are used by employees throughout the project lifecycle to identify, document, and mitigate task related and site-specific hazards.

MAP™

Our proprietary and proactive Maintenance Advantage Program™ (MAP) integrates preventative maintenance with corporate health & safety and transportation compliance programs. This comprehensive fleet management program results in total fleet and equipment support with an emphasis on prevention.

Training

Employees receive extensive classroom and on-the-job training that pertains to their roles. All Cascade field and operations personnel are trained in accordance with OSHA 1910.120 Hazardous Waste Training requirements.